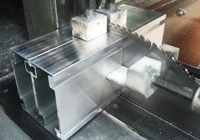

MECHANICAL MACHINING

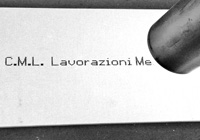

The mechanical machining department is provided with modern numerical control machines that can do the following operations: cutting profile extrusion from a minimum of 4mm to a maximum of 10000mm, drilling, milling, countersinking, tapping, boring, tumbling, vibro-sanding, particolar dryings, branding on the single element, assembly, packaging besides providing a service of external treatment such as oxidation, painting, pvd cladding, chromium-plating and galvanization.

Every operation above mentioned can also be done on behalf of third parties and we can plan and manage the supply of the raw material when required. During the entire productive process and at the end of it, we carefully check samples that allow us to guarantee a high-quality finished product.

|

|

|

| CUT | DRILLING | MILLING |

|

|

|

| BORING | TAPPING | CUT |

|

|

|

| BRANDING | ASSEMBLY | PACKAGING |